THE FORGOTTEN LAMONT BOILER

23 April 1998

by George Nutz- MemberSACA/Northeast

HISTORY

Navy Lieutenant Commander Walter Douglas Lamont was a brilliant engineer who advanced the idea of parallel flow forced circulation non-drum boilers in the late 1920's. The idea was originally proposed and tested by Martin Benson in 1856 and later experimented with by the great Herreshoff but it was Lamont that brought the idea to fruition. Lamont was a great patriot as well as an inventor and he died a sudden and early death; the headlines proclaimed "Navy Man Dies of a Broken Heart" and "Nazis benefit from invention spurned by U.S.". The Lamont boiler concept was lighter, safer, with much higher rates of heat transfer and evaporation per square foot than standard water tube boilers of his time. A large Lamont boiler of 100,000 pounds per hour of evaporation could be started in 15-20 minutes from cold and was ideal for peak overload conditions and was unaffected by high water salt content. The Navy and U.S. companies were committed to the B&W type and had no interest in his designs. Over one thousand were built in Europe, mainly by Germany and also Japan. When WW II broke out many of the fastest German and Japanese ships used Lamont boilers, including the Bismark, and could outrun our fastest steamers. These lightweight fast steaming boilers were made in outputs of up to 500,000#/hr at 1,420psi and 942 degrees steam. Lamont was very depressed that his inventions were used by the enemy and shunned in the U.S. and this led to his early demise.

OPERATING PRINCIPLES

:The Lamont boiler is like a big Doble F boiler in that it has a large helical furnace wall and helical coils top and bottom. The furnace is large and the water in the coils is force circulated at more than 5 times full boiler output. Thus very high heat transfer and radiation rates can be designed for with complete safety as the tube walls are nailed to a temperature a few degrees higher than the steam-water saturation temperature. Heat absorption rates as high as 60,000BTU/ft.sq. for the entire boiler surface were possible and evaporation rates as high as 47#/ft.sq obtained. Compare that to a Doble F with exhaust turbine fan booster at highest output of 26,000BTU/ft.sq. and almost 20#/ft.sq. evaporated and running at the ragged edge of possible tube overheating. The price to pay is a small outside vertical drum with a small circulating pump of a few psi. pressure differential that does the forced circulation in the very high heat areas of the boiler. In a Doble or White the circulation ratio is nominally one, with pumps momentarily off, zero and with pumps catching up, possibly two. The great success to the White and Doble F boiler was a fast control system and massive amounts of feedwater available as these boilers had a safety time constant of 15-20 seconds. The Stanley had such storage and water mass that simple control systems and low pump capacity could be used safely as the boiler at full output had several minutes of reserve water capacity before the crown sheet and lower tube temperatures would rise substantially. The upper sections of the Lamont boiler (bottom fired) were basically stacks of spiral coils cooled by incoming feedwater a la Doble.

LAMONT ADVANTAGES:

Very high heat transfer rates safely available, large reserve capacity due to water in vertical drum, simple control systems adequate with safety, forced circulation until drum runs dry (a pressure differential safety switch on the circulation pump can shut off fire), low carbon inexpensive lightweight thinwall tubing can be used with complete safety, large firebox allows for 45-50% of all heat transfer to be absorbed in fire box by radiation; this allows less spiral coil stacks needed for complete heat transfer and lower blower horsepower for convective heat transfer. Up to two minute time constant requiring smaller water pumping capacity, less tubing length and weight than a Doble F, virtually no salt or carbon buildup on inner tube walls as there is always considerable water in circulation to take everything back to the vertical drum and blown out of the bottom, no scale trap necessary for same reason (Abner Doble pointed out that deposits only occurred at the very end of the evaporation zone where there was no liquid and required periodic sandblast removal). Balanced radiant/convective superheater gives balanced output temperature under all load conditions and precludes the need of a normalizer system. Can be top or bottom fired with little design change.

LAMONT DISADVANTAGES

:Requires a small vertical external drum and the power to drive a small recirculating pump with high pressure pump seals. I have designed a small Lamont boiler for a member of our club that could be used for car or boat so that we could have comparisons of its performance compared to a 20HP Stanley boiler, a 4OHP White boiler, and a Doble F 75HP boiler (electric blower without turbobooster).

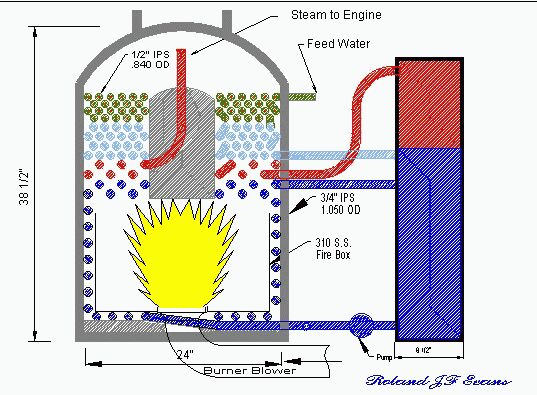

OUR SMALL LAMONT DESIGN

:Member Rod Teel has agreed to build the prototype design for his future boat; it will have a 6gph. #1 oil firing rate derated from its total capacity of 8GPH. His design that has taken over 100 hours of theoretical heat transfer and stress analysis, uses 285 feet of tubing, has a total heating surface of 40sq.ft. (the Stanley has 100, White 46, Doble 80sq.ft.). The Stanley, if 14 inches in height, has 800 feet of tubing, the White 243 feet, the Doble F 558 feet. This Lamont boiler will be 22"0D and 28" high and weight with casing and burner a hopeful 325 pounds including the eight inch vertical drum. It should have a 80% thermal efficiency (the Stanley with 4GPH firing rate had 78%, the White with 48# gasoline/hour=8 gallons appears to have had 70%, the Doble F with a 78#/hr=13GPH had 80% efficiency. Again the small Lamont boiler should weigh all up 325#, the Stanley 500#+, the White 40HP 315# and the Doble F 484#.

A comparison of heat transfer efficiency per square foot reveals the 20HP Stanley (with a 4GPH firing rate that some have pushed to 6GPH) has a heat rate of 4,200 BTU/HR/FTSQ. and evaporation rate of 3.2#/HR/FTSQ. without economizer. The White had a heat rate of 14,300 BTU/HR/FTSQ and evaporation rate of 10.6#/HR/FTSQ with feedwater heater. The Doble F without the exhaust turbobooster had a heat transfer rate of 15,400BTU/HR/FTSQ and a evaporation rate of 11#/HR/FTSQ. The comparative Lamont has a heat rate of 21,400BTU/HR/FTSQ and an evaporation rate of 18#/HR/FTSQ. This is with a steam rate of 326#/hr for the Stanley, 488#/hr for the White, 886#/hr for the Doble F, and 700#/hr for the small Lamont. Let us look at another comparison where we compare the evaporation rate per pound of boiler weight. The Stanley evaporates 0.66# water per pound of boiler weight, the White 1.55#/#, the Doble F 1.83#/# and the proposed Lamont 2.2#/# boiler weight. I stress that the Stanley boiler and Doble F boiler were capable of increased output with modified burners and higher heat release, I mentioned the maximum Doble F performance on page one. Please forgive typographical mistakes and possible errors in data; I would certainly enjoy input from those of you closer to the cars and there data so I could correct any mistakes made.

BOILER COMPARISONS

|

BOILER TYPE |

20 HP STANLEY |

40 HP WHITE |

75 HP DOBLE |

LAMONT |

|

BOILER WEIGHT COMPLETE |

500+# |

315+# |

484+# |

325+# |

|

TUBING LENGTH |

800 FT |

243 FT |

558 FT |

6GPH 250 8GPH 285 |

|

TOTAL HEATING AREA |

100 SQFT |

46 SQFT |

80 SQFT |

8GPH 40 SQFT |

|

FIRING RATE FUEL TYPE |

4GPH /27#/ HR KERO |

8 GPH /48# GASOLINE |

13 GPH /78# GASOLINE |

8 GPH /55# KERO |

|

STEAM RATE #/ HR |

326 |

488 |

886 |

750 |

|

THERMAL EFFICIENCY |

78 % |

70 % |

80 % |

80 % |

|

HEAT TRANSFER RATE 1000 BTU SQFT /HR |

4,200 |

14,300 |

15,400 |

21,400 |

|

EVAPORATION SQFT /HR |

3.2 |

10.6 |

11.1 |

18.0 |

|

EVAPORATION # BOILER WEIGHT |

.66 |

1.55 |

1.83 |

2.2 |

|

APPROX SIZE DIA X HEIGHT |

23 DX 30 H |

22 DX 24 H |

23 DX 32 H |

22 X 28 H PLUS 8" DRUM |

|

RESERVE CAPACITY |

LARGEST |

LEAST |

MEDIUM |

LARGE |

|

CIRCULATION |

POOR |

± 1 |

± 1 |

5 |

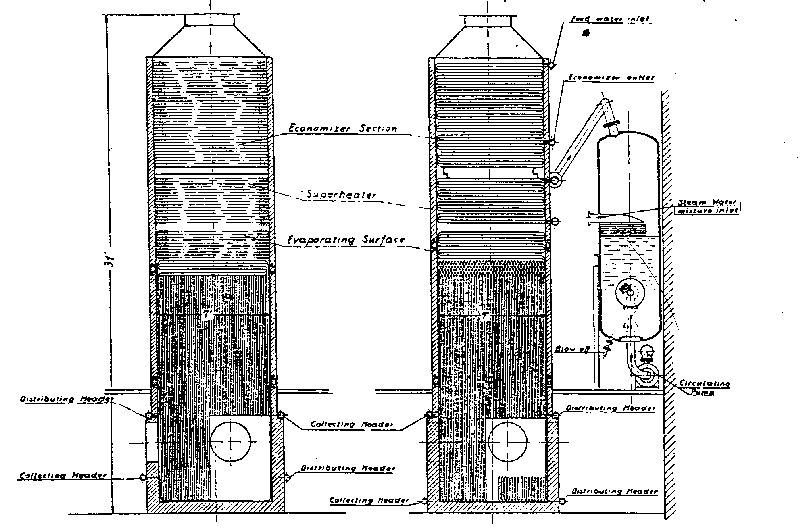

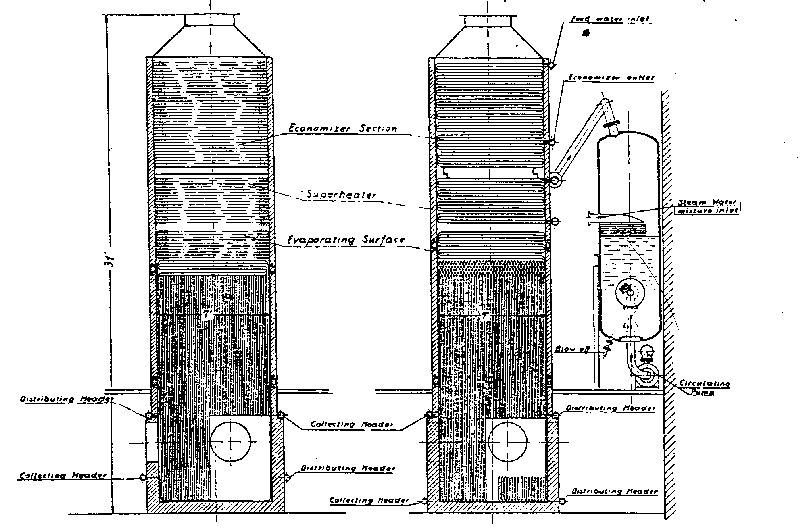

I certainly believe the Lamont design has it over the other examples in simplicity of controls with higher heat transfer and water evaporation rates with less boiler weight, with almost absolute safety. One of the German boilers ran over 60,000 hours without maintenance including pump and seals. It does not require special tubing (the superheater is stainless) and as heat storage reserve is contained in the drum thin wall tubing can be used. Another advantage is that the entrance of steam/water mixture to the vertical drum is of tangential design giving the steam and water a centrifuge affect that acts as a dryer and aids in the forced circulation effect as the water inlet to the circulating pump is also tangential. I have refrained from using finned tubing as any malfunction of the burner can soot and clog finned tubing very quickly and none of us when on the road or water would want to deal with this situation. Several modern very high tech boilers have been built with finned tubing of ultra low weight with ultra fast control systems and I wonder how truly safe there were under fast load fluctuating conditions. The simplicity of the Lamont design and its advantages are worth consideration. On the next page will be a diagram of a Lamont peak load boiler, this boiler being very large did not have a helical coil in the firebox wall but a continuously folded vertical wall of several parallel tubes.

The last page is an artists conception of a small Lamont.

Its all the same theory, circulate it all at 5-10 times boiler output and its perfectly safe!

Back to

Papers Last update: 7 April, 2001.