Once-through boilers have forced circulation because a pump forces water through the generator tubes;

because the water goes through in one pass, they have no recirculation. Natural circulation is brought

about by differences in density caused by heating and usually involves repeatedly circulating the water

through the coils because a single pass is insufficient to convert all the water into steam; the water

recirculates but the recirculation is not forced.

A smaller and lighter boiler can be obtained by aggressively forcing water recirculation with a pump,

this guaranteeing circulation rates high enough to avoid DNB and permitting harder firing with greater

steam production. ‘Forced recirculation boilers’ may provide reserve capability similar to a fire tube

boiler by circulating water to and from a storage drum, the drum also permits contaminants to settle out

without causing harmful deposits on the tube walls. The drum and pump ensure the tubes are always

flooded and the surface areas devoted to generating and superheating steam are of fixed size, control is

simpler than a monotube with the feed water admission rate controlled by the drum level and the firing

rate controlled by the steam pressure. Potential drawbacks include extra weight, cost, maintenance and

whatever reliability issues are associated with the pump. Although forced recirculation boilers long

preceded him, Walter Douglas LaMont championed and developed the concept like no one before and as

a class they are generally referred to as LaMont boilers.

LaMont boilers are very rare in steam automobiles, a strange oversight given the potential for high

performance. The abortive French-Coats automobile used a variety of forced recirculation while the

experimental International Harvester tractor used a jet pump to accelerate recirculation, as did the

production Toledo steamer of 1900 and a few others. Steam car enthusiasts are currently giving forced

recirculation a second look and mostly like what they are seeing; more than one planned or ongoing

home build project boasts a forced recirculation boiler, making the concept worth discussing here.

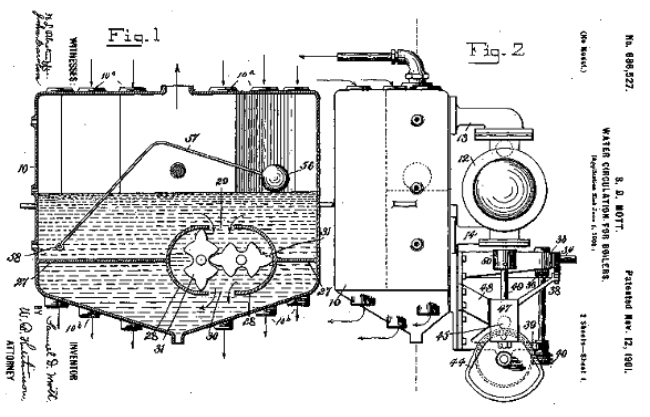

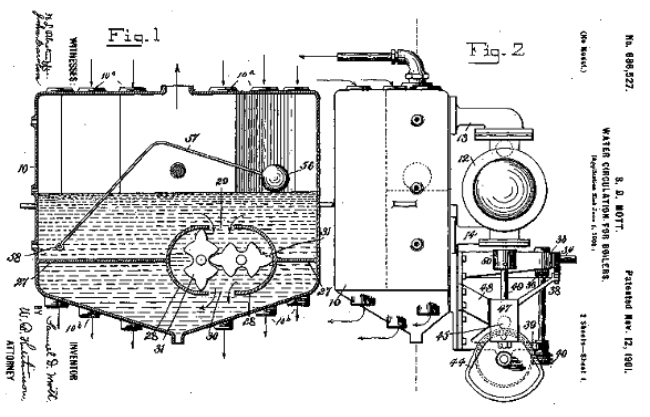

The water drum (cross section, left)

comprises two chambers; the upper

holds the water/steam mix while the

lower is water filled. Tubes

connecting the chambers extend

from the bottom of the lower to the

top of the upper and pass through

the burner. A gear pump between

the chambers forces water from the

upper to the lower; displacing water

through the heated tubes with the

resulting steam/water mix arriving

in the upper chamber.

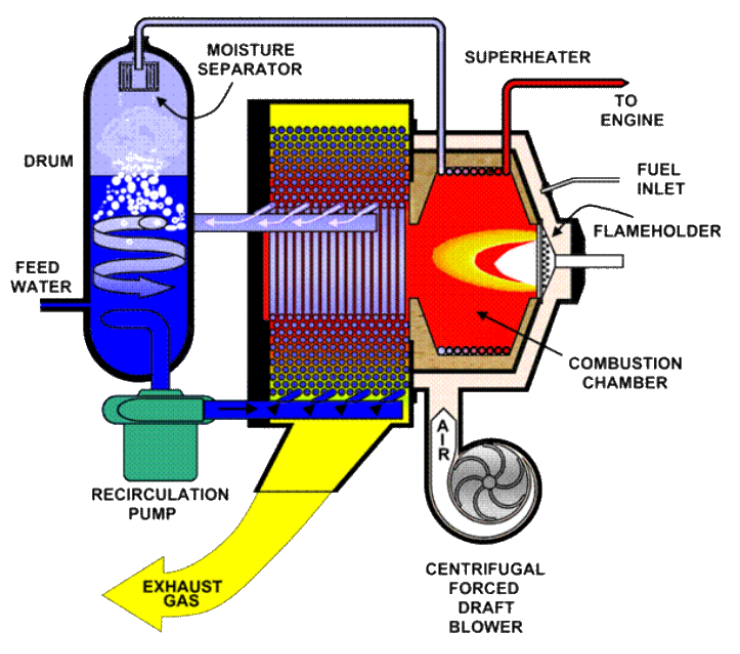

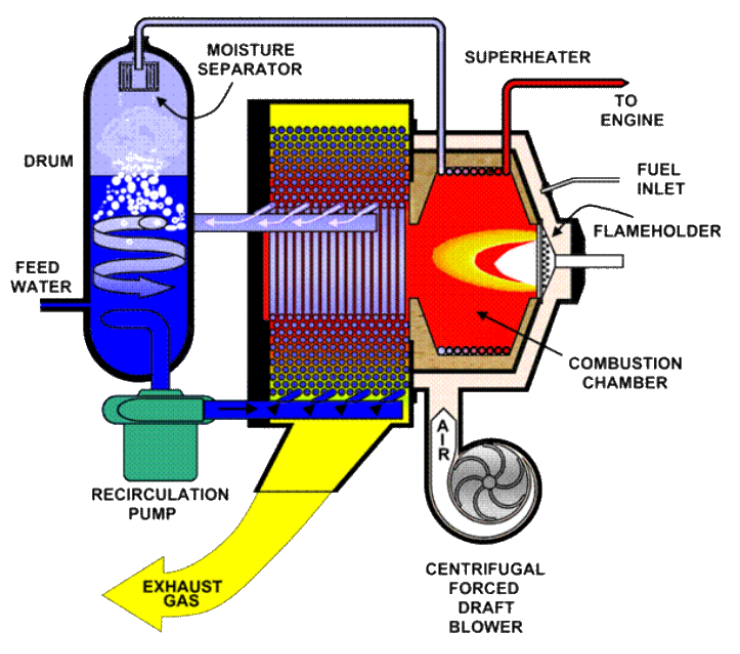

The drawing, below, illustrates a forced recirculation system. The pump (lower left) draws saturated

water from the drum, forcing it through the bottom manifold and into the parallel coils. Spiraling

inwards towards the central fire, the steam/water in each tube reaches the inner manifold and reunites.

The combined flow re-enters the drum at a swirl-inducing tangent, the velocity now being faster than at

the pump due to the increase in volume caused by heating. Centrifugal force drives the heavier water

component outwards to the drum wall, where it descends, while the lighter steam component moves

inwards and rises. The water enters the pump suction at another tangent, converting the water velocity

into a pressure head that assists the pump. The steam rises above the water surface, passes a separator

composed of a labyrinthine passage designed to remove entrained water and then passes out of the drum

to a superheater coil in the fire box and then onto the engine.

Combustion starts with a centrifugal fan (lower right) supplying forced draft to an annular housing

surrounding the combustion chamber, the air absorbs heat emanating from the chamber and entering the

chamber returns it, improving economy. Fuel sprayed into the air just prior to the flame holder

guarantees a good mix and, through evaporation, wicks off heat potentially harmful to the flame holder.

The fuel/air mix passes through the flame holder and ignites, producing an intense flame which

superheats steam in the coils encircling the combustion chamber, absorbing this heat they in turn protect

the chamber walls. Hot combustion gasses flow outwards around the tubes of the coil stack where the

outer shell directs them to the exhaust duct at the bottom.

LAMONT

(FORCED RECIRCULATION)