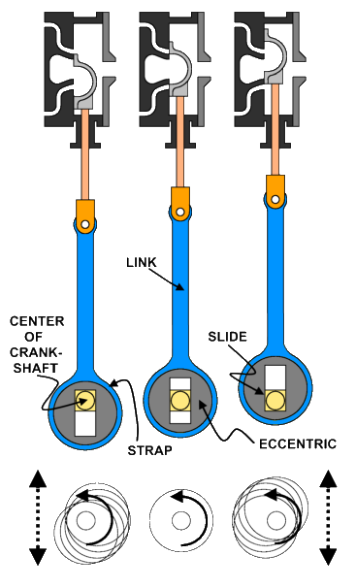

Valve gears modify the valve motion to change cutoff or

reverse the engine, the sliding eccentric being among the

simplest types.

An eccentric pierced by a rectangular slot resides on, and is

revolved by, a square extension of the crankshaft. A

mechanism (not shown) slides the eccentric perpendicular to

the square shaft, changing the orientation and eccentricity.

The amount of cutoff and direction of engine rotation is

regulated by the orientation and magnitude of eccentricity:

The left view shows the engine in forward motion, the

eccentric is in the low position with the valve admitting

steam to cylinder top half and exhausting the bottom.

The center view shows the engine in neutral, the

eccentric is coaxial with crank valve and the valve

blocks flow to and from the cylinder.

The right view shows the engine in reverse, the

eccentric is in the high position with the valve

exhausting the cylinder top half and admitting

steam to bottom.

The sketches at the bottom of the drawing illustrate the

motion of the eccentric as the crankshaft revolves.

Increasing eccentricity increases overall motion and amount

of cutoff.

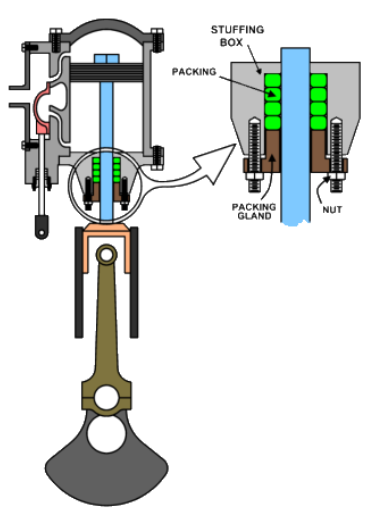

Packing minimizes the escape of steam along the

piston and valve rods. Traditional packing

materials are square woven sections of mixed

cotton, flax, asbestos, hemp or other fiber soaked in

an oleaginous (greasy) substance to limit friction.

Graphite and mica often serve as friction reducing

additives and sometimes brass discs are added for

stability. The piston or valve rod passes out of the

engine via a chamber called the stuffing box; the

packing is wound around the shaft and compressed

against the shaft and stuffing box walls by a

packing gland to form a sliding seal. Modern

packing materials include Teflon, carbon filament,

bearing metals as babbit, Kevlar and flurosilicones.

Simple, Double Acting, Slide Valve Steam Engine, page 2

The animation illustrates the pressure and temperature throughout a stroke for a traditional steam

engine. While DA engines produce power when the piston moves in both directions, we will keep

matters simple only showing the flow to and from the left hand side of the cylinder. The “D” valve

(top center) directs hot steam to the cylinder and cuts it off at about ¼ stroke (red) and directs cold

low pressure steam from the cylinder to the exhaust port (blue). The gage (at left) records cylinder

pressure and color indicates steam temperature, red being hot and blue cool with various shades

showing intermediate temperatures. A device using very similar principles was used to produce

graphs much like those that illustrated Mean Effective Pressure on the last page. The moving dot

following the piston indicates cylinder volume and pressure at any given point in the stroke.

The events in a steam engine expansion cycle, starting at the top left and traveling clockwise, are:

ADMISSION. Hot and pressurized steam enters the cylinder and gives up some energy by working

against the piston; pressure and temperature do not drop significantly because more steam directly

from the boiler enters through the valve.

EXPANSION. Cutting off the steam flow into the cylinder causes the temperature and pressure to

drop steadily as the steam energy is transferred to the piston, which in turn causes the engine to

produce power. Delaying cutoff allows more steam into the cylinder, increasing power but reducing

expansion; steam pressure and temperature fall less, indicating the engine is extracting energy from

the steam less efficiently.

RELEASE. Pressure and temperature plunge as the valve opens, allowing cylinder contents to exit the

cylinder.

EXHAUST. The valve allows the cylinder contents to continue exiting the cylinder as the piston

returns to the beginning of the stroke, pressure and temperature stay low.

COMPRESSION. The valve closes, trapping a small amount of steam in the cylinder. The continued

progression of the piston packs the steam into a small volume, raising temperature and pressure.

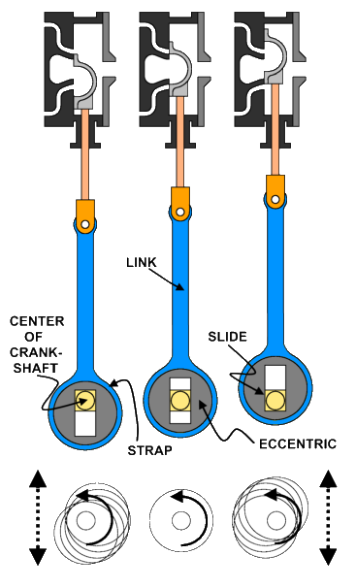

Packing minimizes the escape of steam along the

piston and valve rods. Traditional packing

materials are square woven sections of mixed

cotton, flax, asbestos, hemp or other fiber soaked in

an oleaginous (greasy) substance to limit friction.

Graphite and mica often serve as friction reducing

additives and sometimes brass discs are added for

stability. The piston or valve rod passes out of the

engine via a chamber called the stuffing box; the

packing is wound around the shaft and compressed

against the shaft and stuffing box walls by a

packing gland to form a sliding seal. Modern

packing materials include Teflon, carbon filament,

bearing metals as babbit, Kevlar and flurosilicones.

Simple, Double Acting, Slide Valve Steam Engine, page 2

The animation illustrates the pressure and temperature throughout a stroke for a traditional steam

engine. While DA engines produce power when the piston moves in both directions, we will keep

matters simple only showing the flow to and from the left hand side of the cylinder. The “D” valve

(top center) directs hot steam to the cylinder and cuts it off at about ¼ stroke (red) and directs cold

low pressure steam from the cylinder to the exhaust port (blue). The gage (at left) records cylinder

pressure and color indicates steam temperature, red being hot and blue cool with various shades

showing intermediate temperatures. A device using very similar principles was used to produce

graphs much like those that illustrated Mean Effective Pressure on the last page. The moving dot

following the piston indicates cylinder volume and pressure at any given point in the stroke.

The events in a steam engine expansion cycle, starting at the top left and traveling clockwise, are:

ADMISSION. Hot and pressurized steam enters the cylinder and gives up some energy by working

against the piston; pressure and temperature do not drop significantly because more steam directly

from the boiler enters through the valve.

EXPANSION. Cutting off the steam flow into the cylinder causes the temperature and pressure to

drop steadily as the steam energy is transferred to the piston, which in turn causes the engine to

produce power. Delaying cutoff allows more steam into the cylinder, increasing power but reducing

expansion; steam pressure and temperature fall less, indicating the engine is extracting energy from

the steam less efficiently.

RELEASE. Pressure and temperature plunge as the valve opens, allowing cylinder contents to exit the

cylinder.

EXHAUST. The valve allows the cylinder contents to continue exiting the cylinder as the piston

returns to the beginning of the stroke, pressure and temperature stay low.

COMPRESSION. The valve closes, trapping a small amount of steam in the cylinder. The continued

progression of the piston packs the steam into a small volume, raising temperature and pressure.

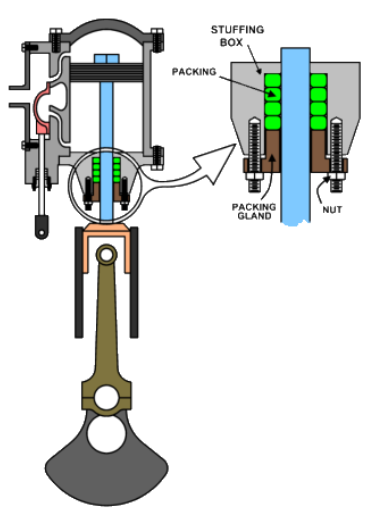

Packing minimizes the escape of steam along the

piston and valve rods. Traditional packing

materials are square woven sections of mixed

cotton, flax, asbestos, hemp or other fiber soaked in

an oleaginous (greasy) substance to limit friction.

Graphite and mica often serve as friction reducing

additives and sometimes brass discs are added for

stability. The piston or valve rod passes out of the

engine via a chamber called the stuffing box; the

packing is wound around the shaft and compressed

against the shaft and stuffing box walls by a

packing gland to form a sliding seal. Modern

packing materials include Teflon, carbon filament,

bearing metals as babbit, Kevlar and flurosilicones.

Simple, Double Acting, Slide Valve Steam Engine, page 2

The animation illustrates the pressure and temperature throughout a stroke for a traditional steam

engine. While DA engines produce power when the piston moves in both directions, we will keep

matters simple only showing the flow to and from the left hand side of the cylinder. The “D” valve

(top center) directs hot steam to the cylinder and cuts it off at about ¼ stroke (red) and directs cold

low pressure steam from the cylinder to the exhaust port (blue). The gage (at left) records cylinder

pressure and color indicates steam temperature, red being hot and blue cool with various shades

showing intermediate temperatures. A device using very similar principles was used to produce

graphs much like those that illustrated Mean Effective Pressure on the last page. The moving dot

following the piston indicates cylinder volume and pressure at any given point in the stroke.

The events in a steam engine expansion cycle, starting at the top left and traveling clockwise, are:

ADMISSION. Hot and pressurized steam enters the cylinder and gives up some energy by working

against the piston; pressure and temperature do not drop significantly because more steam directly

from the boiler enters through the valve.

EXPANSION. Cutting off the steam flow into the cylinder causes the temperature and pressure to

drop steadily as the steam energy is transferred to the piston, which in turn causes the engine to

produce power. Delaying cutoff allows more steam into the cylinder, increasing power but reducing

expansion; steam pressure and temperature fall less, indicating the engine is extracting energy from

the steam less efficiently.

RELEASE. Pressure and temperature plunge as the valve opens, allowing cylinder contents to exit the

cylinder.

EXHAUST. The valve allows the cylinder contents to continue exiting the cylinder as the piston

returns to the beginning of the stroke, pressure and temperature stay low.

COMPRESSION. The valve closes, trapping a small amount of steam in the cylinder. The continued

progression of the piston packs the steam into a small volume, raising temperature and pressure.

Packing minimizes the escape of steam along the

piston and valve rods. Traditional packing

materials are square woven sections of mixed

cotton, flax, asbestos, hemp or other fiber soaked in

an oleaginous (greasy) substance to limit friction.

Graphite and mica often serve as friction reducing

additives and sometimes brass discs are added for

stability. The piston or valve rod passes out of the

engine via a chamber called the stuffing box; the

packing is wound around the shaft and compressed

against the shaft and stuffing box walls by a

packing gland to form a sliding seal. Modern

packing materials include Teflon, carbon filament,

bearing metals as babbit, Kevlar and flurosilicones.

Simple, Double Acting, Slide Valve Steam Engine, page 2

The animation illustrates the pressure and temperature throughout a stroke for a traditional steam

engine. While DA engines produce power when the piston moves in both directions, we will keep

matters simple only showing the flow to and from the left hand side of the cylinder. The “D” valve

(top center) directs hot steam to the cylinder and cuts it off at about ¼ stroke (red) and directs cold

low pressure steam from the cylinder to the exhaust port (blue). The gage (at left) records cylinder

pressure and color indicates steam temperature, red being hot and blue cool with various shades

showing intermediate temperatures. A device using very similar principles was used to produce

graphs much like those that illustrated Mean Effective Pressure on the last page. The moving dot

following the piston indicates cylinder volume and pressure at any given point in the stroke.

The events in a steam engine expansion cycle, starting at the top left and traveling clockwise, are:

ADMISSION. Hot and pressurized steam enters the cylinder and gives up some energy by working

against the piston; pressure and temperature do not drop significantly because more steam directly

from the boiler enters through the valve.

EXPANSION. Cutting off the steam flow into the cylinder causes the temperature and pressure to

drop steadily as the steam energy is transferred to the piston, which in turn causes the engine to

produce power. Delaying cutoff allows more steam into the cylinder, increasing power but reducing

expansion; steam pressure and temperature fall less, indicating the engine is extracting energy from

the steam less efficiently.

RELEASE. Pressure and temperature plunge as the valve opens, allowing cylinder contents to exit the

cylinder.

EXHAUST. The valve allows the cylinder contents to continue exiting the cylinder as the piston

returns to the beginning of the stroke, pressure and temperature stay low.

COMPRESSION. The valve closes, trapping a small amount of steam in the cylinder. The continued

progression of the piston packs the steam into a small volume, raising temperature and pressure.