Hardware and such…

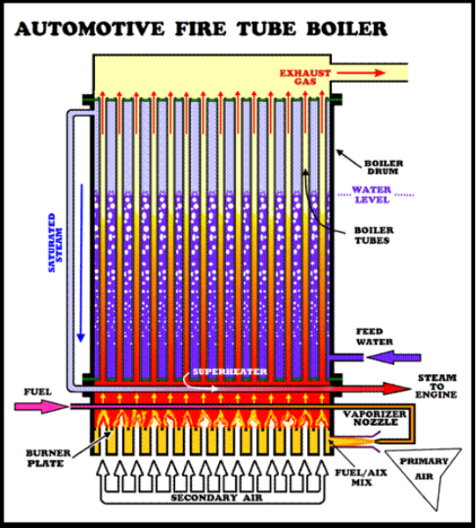

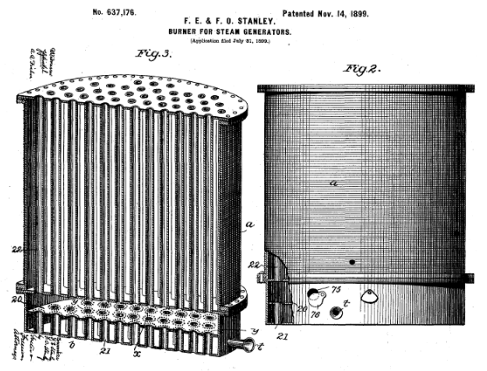

Stanley (generic fire tube)

Liquid fuel under pressure is converted to vapor

in the vaporizer tube, which is heated by the

burner. Upon exiting the nozzle, the pressurized

vapor expands to high velocity (lower right) and

carries primary air through the mixing tube to a

space beneath the burner plate. A number of

small perforations in the burner plate allow the

fuel /air mixture to pass upwards, where it is

ignited, producing rising hot gasses which draws

secondary air through larger holes to combust

unburned fuel. A strong drum encapsulates

tubes through which the hot combustion gasses

pass; water introduced into the shell is

transformed into steam by contact with the

exterior of the hot tubes. The steam collects at

the top of the drum and on its way to the engine

passes through a superheater just above the

burner.

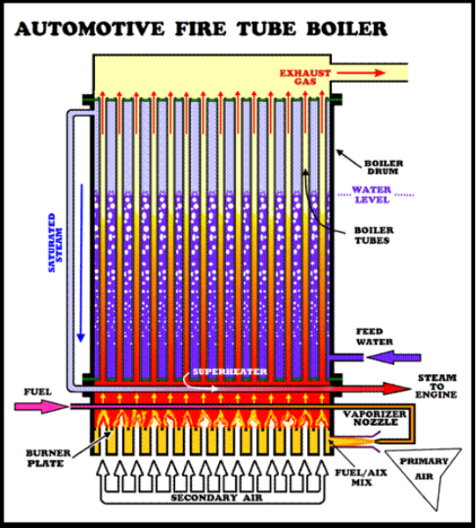

Fire and water tube boilers date to the early

19th century, the fire tube was initially more

popular with water tubes gaining popularity in

the second half of the century. Fire tube boilers

are typically easy to operate, containing a large

amount of saturated water which flashes to

steam upon a sudden drop in pressure; they are

not sensitive to sudden changes in demand.

Fire tube boilers are slow to reach operating

temperature because the heavy shell and large

mass of water absorbs much heat. The sudden

pressure loss accompanying a boiler shell

failure presents a significant hazard; part of

the heated water instantly expands into steam

with explosive force. Recognizing these

potential dangers, the Stanley twins wrapped

piano wire around the shells to provide great

strength and installed copper fire tubes which

fail before the shell and harmlessly channel the

boiler contents to the ground beneath the car.

Stanley steam car images

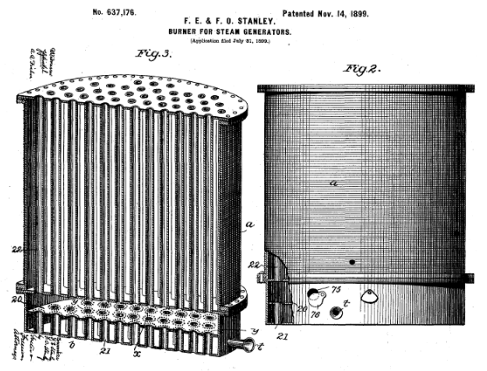

Fire and water tube boilers date to the early

19th century, the fire tube was initially more

popular with water tubes gaining popularity in

the second half of the century. Fire tube boilers

are typically easy to operate, containing a large

amount of saturated water which flashes to

steam upon a sudden drop in pressure; they are

not sensitive to sudden changes in demand.

Fire tube boilers are slow to reach operating

temperature because the heavy shell and large

mass of water absorbs much heat. The sudden

pressure loss accompanying a boiler shell

failure presents a significant hazard; part of

the heated water instantly expands into steam

with explosive force. Recognizing these

potential dangers, the Stanley twins wrapped

piano wire around the shells to provide great

strength and installed copper fire tubes which

fail before the shell and harmlessly channel the

boiler contents to the ground beneath the car.

Stanley steam car images

Fire and water tube boilers date to the early

19th century, the fire tube was initially more

popular with water tubes gaining popularity in

the second half of the century. Fire tube boilers

are typically easy to operate, containing a large

amount of saturated water which flashes to

steam upon a sudden drop in pressure; they are

not sensitive to sudden changes in demand.

Fire tube boilers are slow to reach operating

temperature because the heavy shell and large

mass of water absorbs much heat. The sudden

pressure loss accompanying a boiler shell

failure presents a significant hazard; part of

the heated water instantly expands into steam

with explosive force. Recognizing these

potential dangers, the Stanley twins wrapped

piano wire around the shells to provide great

strength and installed copper fire tubes which

fail before the shell and harmlessly channel the

boiler contents to the ground beneath the car.

Stanley steam car images

Fire and water tube boilers date to the early

19th century, the fire tube was initially more

popular with water tubes gaining popularity in

the second half of the century. Fire tube boilers

are typically easy to operate, containing a large

amount of saturated water which flashes to

steam upon a sudden drop in pressure; they are

not sensitive to sudden changes in demand.

Fire tube boilers are slow to reach operating

temperature because the heavy shell and large

mass of water absorbs much heat. The sudden

pressure loss accompanying a boiler shell

failure presents a significant hazard; part of

the heated water instantly expands into steam

with explosive force. Recognizing these

potential dangers, the Stanley twins wrapped

piano wire around the shells to provide great

strength and installed copper fire tubes which

fail before the shell and harmlessly channel the

boiler contents to the ground beneath the car.

Stanley steam car images