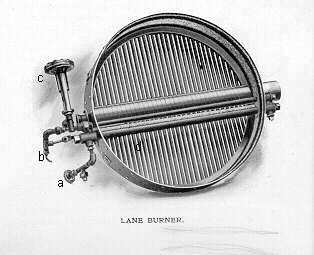

This illustration is from the 1902 Lane catalog.

The Lane Burner

By

Arthur Eldredge

The Lane is of an interesting and different design from most steam car burners. The principle difference is that it is an atmospheric burner as opposed to a fully pressurized burner. By this I mean by that is this: a fully pressurized burner draws all of its combustion air through the mixing tube or tubes and the burner casing is completely sealed, whereas, an atmospheric burner draws most of its combustion air up through the grate. In other words the bottom of the burner is open to the atmosphere.

Now, let's go to the details of the Lane burner design. Referring to the accompanying picture I will describe the construction and operation of the Lane burner. The grate is constructed out of 1/8-inch pipe screwed into a large central tube approximately 2 1/2 inches in diameter. The outer ends of the 1/8-inch pipes are capped and sandwiched lightly between two steel rings. The outer ends are free to expand and contract as the burner heats or cools. The 1/8-inch pipes and the larger central tube are drilled with thousands of holes for the fire. The burner casing is sheet steel with a lining of asbestos paper. A sheet metal pan is installed below the burner to act as a shield from any wind that may be occurring.

This illustration is from the 1902 Lane catalog.

The vaporizer (d) is very simple in construction. It is made of 1/4" pipe with the necessary fittings. Cleaning the vaporizer is done by removing the pipe plugs at both end of the vaporizer pipe and the main jet assembly and clearing any soot with a gun cleaning brush. Underneath the vaporizer is another pipe, which is perforated throughout its entire length and wrapped with asbestos wicking. One end of this pipe capped. This pipe is an alcohol burner used to preheat the main vaporizer when the burner is cold.

This burner has one main jet and a pilot jet. The pilot is nothing more than a traditional gasoline blowtorch and can burn very fiercely indeed! It should be noted that the steam automatic is located at the main jet assembly rather than being plumbed into the inlet side of the vaporizer. The automatic (c) is, therefore, controlling fuel flow to the burner in a gaseous state. Aside from that it works like a Stanley automatic.

Lighting this burner is very easy. First, one must make sure the flue dampers are open to insure a natural draft through the boiler. Also the fuel tank should be pressurized to about 50 psi. At this point, denatured alcohol is poured into a small cup under the seat, which is connected to the wick tube in the burner. Also alcohol is poured into a small cup under the main jet. Both the wick tube and the jet cup are lit with a match. After the jet cup burns out, I refill it and light it once again. In the meantime I add alcohol to the wick tube as needed to keep it lit. After the jet cup burns out a second time, I cracked the main fuel valve (a) and the burner will light. I then let the burner run gently to warm up.

Once there is steam available (25 to 50 psi.). I will turn on the steam draft and then open the main fire valve wide. Next I will turn on the pilot(b). From here on out the burner will take care of itself. It should be noted that the pilot and main fire share the same vaporizer. As a result, the pilot can only be lit after the main fire is going. Once it is lit, the main fire can cycle on and off and the pilot will keep the vaporizer plenty hot.

How does this burner behave in practice? Incredibly well. I have found that once it is lit I can pretty much forget about it. During our recent SACA-NE meetings I have lit the burner shortly after arriving and not touched it for the rest of the day. I can park the car for an hour or more and then climb aboard and drive away without any concern that that fire won't come on properly.

If there is any disadvantage to this burner, it is the fact that the one must use the forced draft when the fire is on hard and the car is stationary. The engine exhaust does provide draft like a locomotive but only when the engine is working, therefore, one must run the forced draft continuously. Only when the car is parked and the main fire is off can one shut off the forced draft. Obviously, having to use the draft all the time consumes a lot of steam. Aside from that one disadvantage, this is a superb burner that is very trouble free. The only normal maintenance that I have to perform is periodic disassembly and cleaning of the main jet assembly. This is due, in part, to the various additives in modern gasolines.

Mr. Eldredge's burner, showing failed alcohol wick tube.

This burner is 100 years Old.

Photo by D. K. Nergaard, taken during SACA-NE August meet.

(22 August 2001)

Back to Papers